Introduction

Lack of space in the warehouse, overly complicated navigation inside it, poor communication between personnel members, and ongoing operation emergencies are only a few signs that you need to improve your warehouse management asap. This article is going to discuss some of the most cutting-edge inventory management technologies and how your business can benefit from integrating them in your daily operations.

Overview of technologies for inventory management

The essence of inventory management is based on such fundamental things as layout design of a warehouse, storing strategy, order-picking organization, and stock keeping unit (SKU) tracking. Nevertheless, even if your business seems to have no flaws when it comes to the listed above inventory management components, this does not guarantee maximum productivity and perfect operations flow. The 2017 E-Commerce Fulfilment Report written by Peoplevox released shocking statistics related to inventory management problems. It says that 46% of problems related to inventory operations occur due to human errors at worksite. Beyond question, 46% is a lot. However, the rest of the issues at warehouse has nothing to do with personnel, but appears because of outdated technology use. Namely, companies that took part in the survey responded that their most frequent problems are linked with the absence of barcodes on items and miscounting of raw materials or goods for sale. The quick overview of the most in-demand warehouse technologies will give you some insight into the state of inventory management as it is today.

|

Inventory tracking with QR and barcodesA code-based inventory system is one of the most frequently used technologies to track products in the warehouse. It requires a scanner — a device that analyzes the code image with camera and deciphers information about a product. Through scanning workers can immediately find out how many of same items are left in stock, cost, size, weight, etc. Not only this technology adds to efficiency of the warehouse audit, it also prevents a sudden shortage of products that are in demand. However, to implement this technology, it is required to obligatory place QR or barcode on every single item, as well as equip personnel with devices that support scanning. Instead of buying actual scanners workers can use tablets or even their smartphones to scan codes with. The only thing that would be needed in that case is an app that supports this function. Such ac cessibility and ease of use made this method one of the best warehouse technologies so far. |

|

RFIDThis is a fully automated way of gathering information about a product or even a pallet of products. With such identification system, item’s data is transmitted with no physical contact. It consists of host terminal, transponder (tags — small memory devices attached to goods and/or pallets), and transceiver (reader). Also, it is not just hardware that is required to buy for RFID integration in the inventory management, but software as well, a merchandise management system (MMS) in particular. If MMS of a warehouse has a mobile version, then workers have permanent access to inventory operations, which in terms decrease the risk of sudden and unnoticed emergencies. Despite this technology requires decent investments and experts to be involved in its installing and operating, it is less labor-intensive than QR or barcode scanning. RFID has impressive potential when it comes to warehouse optimization — it gets product information with no human involved, can read 40 tags in less than a second and scan multiple pallets filled in with mixed products at once. Add to this an ability to indicate error when workers place the product in any storage place other than the one indicated in RFID tag, and you’ll understand why market giants like Amazon appreciate this technology and use it daily to speed up the goods’ journey all the way from manufacturer to distributors. |

|

GPS tracking and logistics managementToday, GPS technology is so much more than just a navigation tool for drivers and pedestrians. It is also used at warehouses of various sizes to track the number and condition of items stored. Great benefit of GPS for inventory management is an ability to access logistic operations (like status of shipping and transits in process) outside the warehouse, as well as control the storage of goods inside it at once. GPS indoor tracking is a technology that lets personnel to prevent products and pallets from missing inside the warehouse, as workers can check the locations of needed items directly from their smartphones or tablets (if GPS-enabled, of course). However, this technology is rarely used on its own; it has relatively high costs and is still in limited use for inventory management. |

|

Voice-directed warehousingIt is the use of voice to control warehouse operations through voice recognition software. Voice technology is structured as follows: workers wear hands-free headsets connected to the WMS with built-in voice recognition software. People pronounce confirmation codes and pre-defined commands, which then are converted into data and even recorded in WMS reports with no paperwork done by humans. Such straightforward approach to inventory management maximizes warehouse efficiency and control over products in stock, eliminates the possibility of errors, and creates paperwork-free environment. Pickers start working faster and more accurately, since the use of vocal control saves valuable time on each operation and reduces time needed for employee training — workers now rely on their speaking skills to perform the majority of warehouse operations. Although voice-enabled warehouse management system requires funds to be integrated in daily operation of inventory, it comes with a relatively short ROI rates from 6 to 12 months max. |

|

RoboticsThis is a cutting-edge technology for inventory management that has already been used at warehouses of such industry giants like Amazon and the world biggest retailer Alibaba located in Huiyang, China. It allows to create an automated warehouse with a comprehensive goods-to-person system. Robots can collect, move, and even sort items in stock without human workers involved simply by receiving instructions directly from the WMS. Clearly, robotic technology is the most expensive to implement and support, as you cannot buy a single robot and expect it to function on its own. Warehouse robots have to be connected with the WMS and CRM suits to perform effectively. This technology is also closely attached to SLAM (simultaneous localization and mapping) — a technique behind robot vehicles and their navigation. Warehouses that implemented robotics ecosystem in their inventory management say that human labor decreased by 70%, which added points to the productivity of the supply chain in general. |

Warehouse Management Software

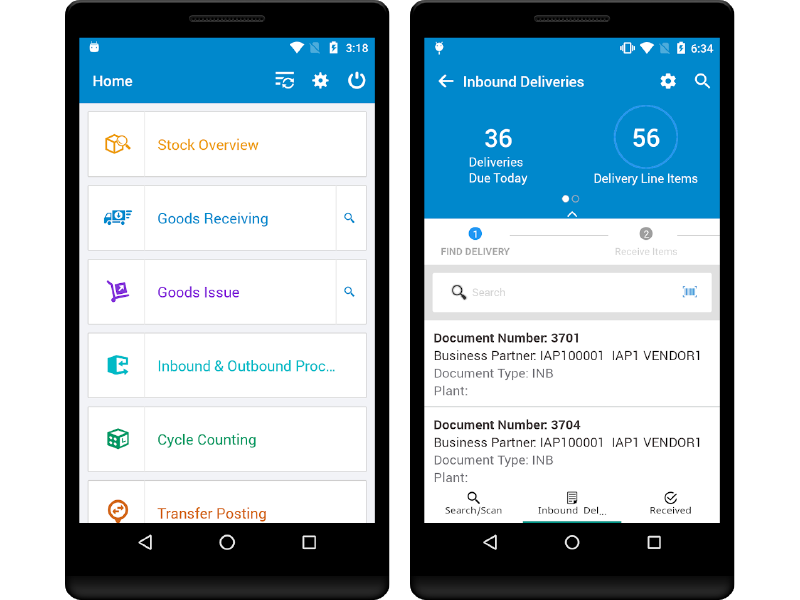

WMS is a comprehensive system that manages and controls all the operations within an warehouse. Without an efficient software, business has minimal chances of growing, as taking control over such operations as intake of items, storage, picking, stock tracking, and shipping is no piece of cake. Understanding that, a lot of software development companies decided to focus on creating warehouse management solutions for sale. A company can use a standalone program or integrate it in a more far-reaching supply chain management system or enterprise resource planning. Getting a readymade WMS seems to be cheaper and easier than hiring a team for developing your own system, however, it is less customizable and will unlikely fit your business model perfectly. Meanwhile, enterprises who opt for development of their own warehouse inventory management software get an effective solution targeted to their needs without unnecessary extra features.

Regardless of company’s choice, the WMS integrated will most likely have the following features:

- Inventory control. This function allows to track products in the warehouse and control stock adjustments.

- Movement of stock keeping units.This includes oversight of picking, fulfilling, receiving, and shipping all the items in stock.

- Software integration. An ability to have all the information about inventory operations and real-time updates from various supply chain systems is essential for avoiding any kinds of emergencies like overstocking or unnoticed equipment breakage. This function also includes support of QR and barcodes scanners reporting, voice control, RFID, and any other technology warehouse managers would like to implement in their daily operations.

- Third-party logistics. This feature includes shipping done by third-party teams, namely its tracking and reporting the outside payments.

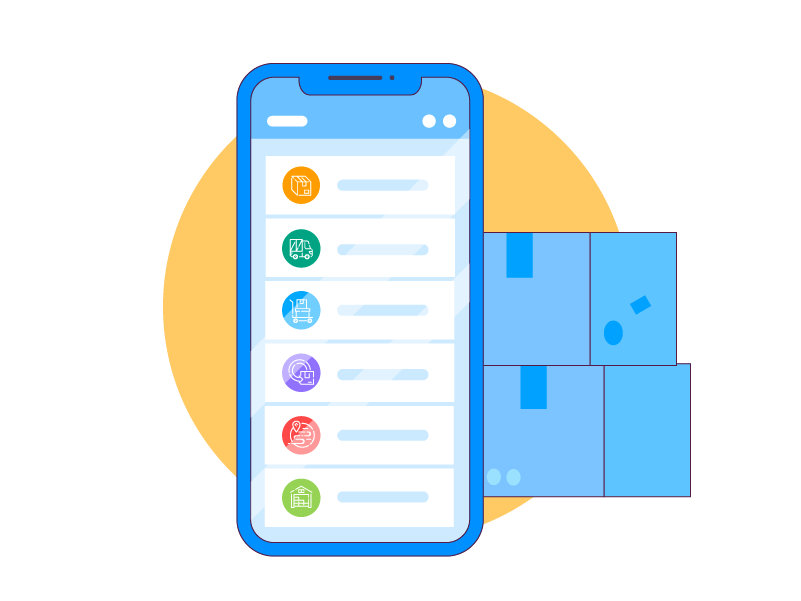

A separate word should be said about the multiple device support feature. Probably, it is the most important one out of all discussed above, as an accessibility is crucial when it comes to warehouse management. Workers constantly move inside the building and they would literally have no time to sit at the computer or laptop to report or find the needed information.

Also, PCs does not have an inbuilt scanner, which is a must-have device for the majority of SMBs. As Motorola Solutions study reports, by the end of 2018 warehouse managers will decrease the amount of paper-based work by 71% and implement the obligatory use of tablets and/or smartphones to track inventory processes. This means two-thirds of companies will soon drastically improve their operations resulting in better customer experience and business growth. For programmers, this indicates the need to focus their warehouse optimization software development not just on desktop version, but on warehouse mobile apps as well, as now this kind of product is in a very high demand and its popularity will not decrease anytime soon.

Inventory management apps: types, development, and benefits

If you are a retailer or a wholesaler, then your top priority is probably the rapid growth in sales combined with positive buyers’ experience. However, if the inventory is not managed properly, the sudden burst of sales might become a nightmare for warehouse managers and even ruin the positive image of a company. To conquer and prevent any kind of warehouse emergencies, programmers introduced to business owners inventory apps — an ultimate tool that gives warehouse management access to literally any employee having a smartphone or tablet.

Basically, there two types of mobile applications that are actively used in warehouse management: asset tracking appsand inventory tracking apps. Sometimes, people may use these two terms interchangeably, but this is not actually correct. The thing is that both of such apps might include QR or barcode scanning, but asset tracking also involves company’s property, machinery, etc., while inventory tracking focuses on raw materials, working process, and items to merchandize. A company might use both of these programs, but warehouse managers would definitely need an inventory app installed on their tablets or smartphones.

Since warehouse management apps quickly proved their effectiveness and became a popular product on the IT market, a lot of companies quickly created ready-made inventory apps that you can easily buy and start using without spending tons of money. However, not all the business owners jumped over to integrating such apps into daily operations of their warehouses. Why? Just because they come with certain disadvantages, from unstable work and occasional system crashes to weak cyber protection of data and absence of versatility when it comes to extra features.

ntrepreneurs occupied with such troubles were forced to seek another solution that would let their warehouse to operate seamlessly, namely a custom inventory app development.

So what does it actually take to build a warehouse app? From the perspective of a business owner, you have to think through the case of your company and define typical challenges your employees face at workplace. Also, you should consider the following aspects, that would later define the actual app development:

|

Innovation readinessEven if the top managers would like to implement high-tech in the warehouse operations, this does not guarantee the success of the whole deal. Before starting to review WMS options available, ask yourself if your workers are able to use programs and apps effectively? If the answer is “no”, that this would be the foremost task to deal with. |

|

Approximate number of usersNot all the applications can provide stable work with the big number of users, so you should keep in mind not only the current number of employees, but the prospective changes in this number as well. |

|

Volume of inventory usually in stockThe amount of inventory you stock now and its potential growth in future are defining factors when developing an app. It should be able to export and import big volumes of data and process the information quickly. |

|

Specific kind of inventory storedSuch fields as food supply or pharmacy require specific inventory management technologies due to the more complex storing conditions, which means a more sophisticated software with extra features is needed (e.g., notifications on the approaching expiration). |

|

BudgetCome up with the number you are ready to spend on your inventory system, but keep in mind that a cheaper solution might be less effective and reliable, and that might cost you more in the future. |

|

HardwareA first thing that would come to most minds when it comes to operations management is definitely a personal computer. However, as we have already mentioned earlier, it’s not the case with inventory managers. These guys do not sit at their PCs, they are on the go from start to finish of the working day thus have no ability to carry anything bigger than a tablet with them. |

|

Operating systemIf you do not want to limit your workers to a single operating system (for example, iOS that is available only on Apple gadgets), make sure the app of your choice is supported on various platforms. |

|

VersatilityIf you want your WMS to team up with other programs you already use, for example for time-tracking or financial operations, check out what kind of solutions are suitable for you. |

After you have gathered all the required data, the rest is the app developers’ task. Although the development process will take some time, a powerful inventory management app is worth waiting for. Inventory applications deliver impressive results in warehouse optimization, as they connect managers with real-time observation of stock keeping units, orders, picking, delivery, and basically any other activity that takes place within the warehouse. With the development of artificial intelligence and its active use to manage business-related issues, inventory apps will soon become able not only to store data and send alerts to the people when needed, but also to perform the forecasting and planning with no human involved. Managers who got to work with the use of custom-developed inventory application now less exposed to time-consuming physical inventory audits, stressful undersupply, and other manifestations of poor inventory control.

Summary

The high-technology boost we are living in today has drastically changed every single sphere of our lives, including business and warehouse management. What used to be time-consuming, complex and almost unbearable is now fast, easy, and seamless. Modern inventory managers do not spend hours on paperwork or physical checks and SKU accountancy, as now we have software aimed at solving daily challenges without us even noticing them. As we can see, retailers and wholesalers who want their companies to grow substantially, opted for effective software that helps them manage inventory processes with the real-time visibility of all the warehouse operations. High demand for warehouse management solutions that was formed on the IT market years ago is not going no decrease within the nearest couple of years for sure. Vice versa, a tendency of small and midsize businesses reaching for custom WMS development makes this niche a promising sector of the global SaaS market.