2020-2021 became a dark time for supply chain companies because of the global cargo crisis. All businesses, from Amazon to Johnson & Johnson, felt the pressure of unoptimized routes, high complementary costs, and a lack of powers to change the conditions. Fortunately, IoT technology opened various opportunities for enterprises to withstand such significant unexpected challenges. The Internet of Things was just the beginning of another popular technology – the digital twin.

Geese saved Ancient Rome. Digital twin saved supply chain. It is credited with the leading role in the supply chain recovery in such a short period. Note that the complex geopolitical situation no longer affects this industry as destructively as the pandemic. Someone will say this is all about the relevant experience of survival in extreme conditions. Of course, but it’s just the tip of the iceberg. The basis is the digital twin.

Scroll down to explore what digital twin is, why it became a catalyst of qualitative changes in the supply chain, and how businesses can boost the industry with this technology.

Related: How are Retailers Doing This Holiday Season: General Overview

What is Digital Twin: Supply Chain Perspective

About digital twins in general

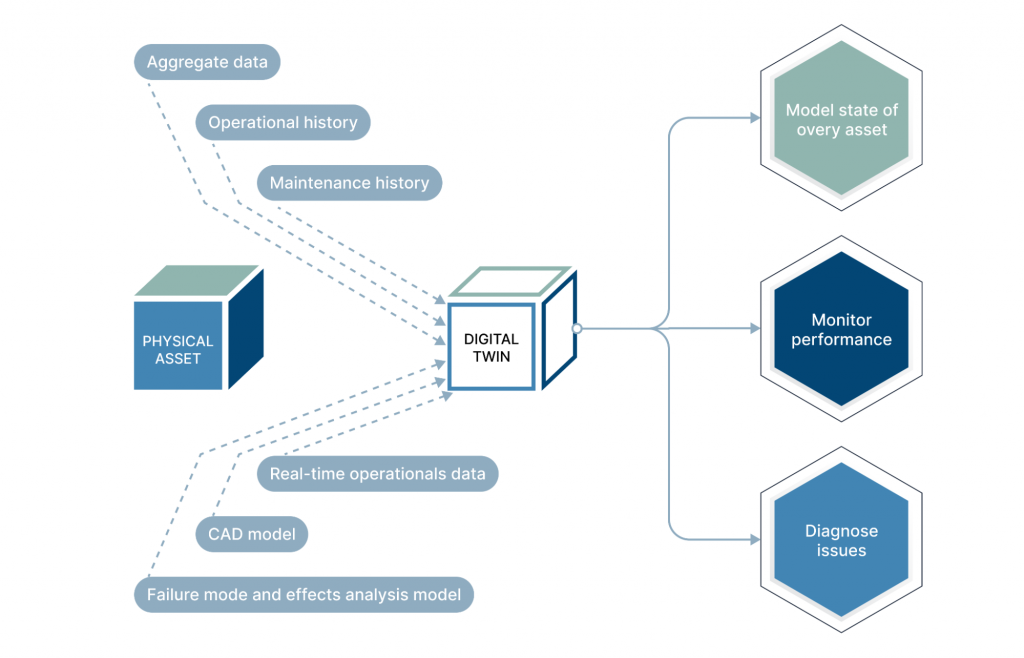

For supply chain companies, a digital twin is a core technology that helped them to cope with the global crisis. It’s an accurate virtual copy of real assets, processes, departments, companies, and even people, which allows business leaders to see a bigger dynamic picture illustrating the object’s operation in real time.

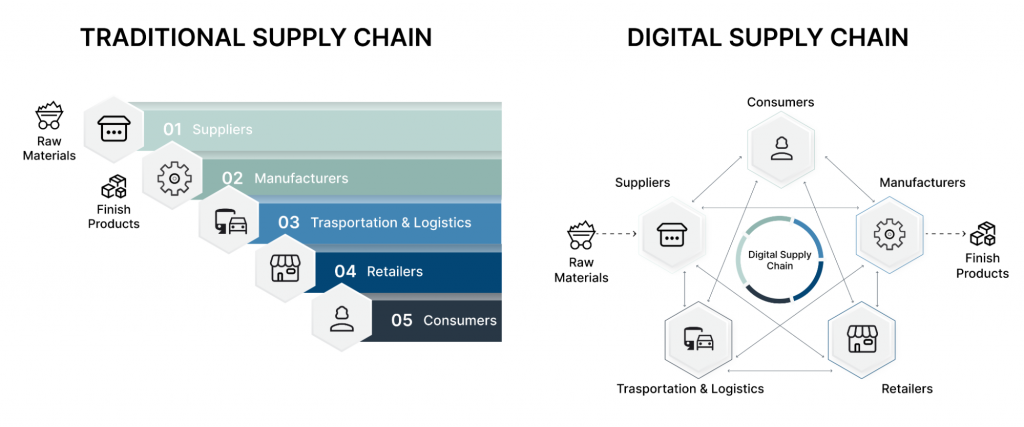

Just imagine the entire supply chain process. It consists of suppliers, distributors, goods, transport, routes, permanent back office work, etc. The slightest error in the transportation conditions, whether the time or temperature inside the container and at least the supply agreement terms, will be violated. While the worst scenario is that the end consumer will not be interested in accepting or buying the goods due to late delivery or poor quality.

Supply chain companies should control and predict everything around them because their businesses work due to accurate data and the well-organized work of each element in the system. Since pitfalls wait at every step, robust software support is indispensable. Fortunately, a digital twin is a tool helping companies perform attentive control and management over the supply chain because of its comprehensive functionality and the IoT basis.

Related: Technology in Supply Chain Management: How Innovation Boosts The Industry

How does a digital twin work?

A digital twin is a virtual copy created based on real-time data transmitted on an IoT device management application from thousands of devices placed in vehicles, goods, and even on employees’ wrists. Smart sensors can track everything: the temperature and humidity levels, drivers’ health, traffic jams, or vehicle performance problems. These data representing each factor accompanying the shipment allow you to create a full-fledged virtual supply chain model.

How to get digital twin software?

Since enterprises need to keep track of everything to work flawlessly, they process data from sensors and all connected devices, from smartphones to satellites. Not every company can afford to work with Big Data since multifunctional and accurate digital twins are always about time-consuming development cycles, high cost of creation & ownership, and 24/7 support. Therefore, the biggest software vendors, such as SAP and Oracle, created virtual twins for supply chains tailored to the industrial reality. Other companies like TransVoyant have also carved a niche in this process. They help supply chain companies by providing predictive analytics on weather conditions, traffic, etc.

Who is using digital twin in the supply chain?

A digital twin is used by all enterprises implementing IoT and working seamlessly due to supply chain uninterrupted processes. Therefore, all large retailers such as Amazon, Walmart, and Kroger, manufacturers like Bosch, and other businesses boost their supply chain with this technology. The rapid adoption of digital twins was vital in a pandemic since the conditions required quick and correct transformation of routes. Companies that have already worked with IoT managed to master digital twins and eliminate challenges in a tight schedule.

Related: How Machine Learning Can Enhance the Supply Chain

The Role of Digital Twin in Supply Chain Management: Top Reasons Why It Helped the Industry Survive

Accurate data from different sources

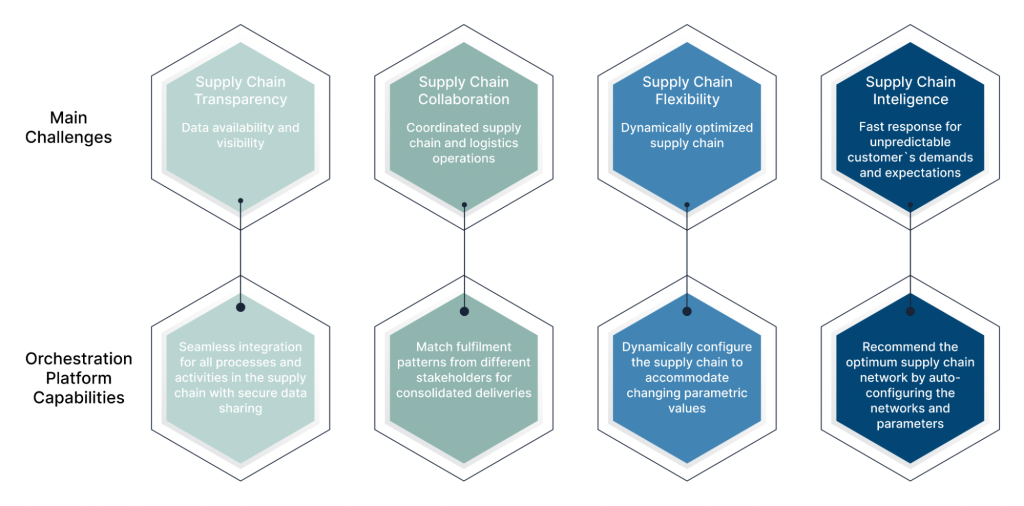

Digital twins, like any other IoT-based technology, can gather devices from various vendors under one roof and ensure centralized data collection and management. This way, companies receive 100% accurate real-time information from thousands of connected sensors. During the global cargo crisis, it helped businesses discover their weaknesses and fix them before they became a real problem.

Painless idea validation

Since the digital twin is an exact virtual copy of the real supply chain, business leaders can use this model as a litmus test to show how effective any change can be. Before initiating projects to improve the supply chain, companies can implement these changes in the digital prototype and evaluate the results. The advantage is that such validation does not cause any harm to current processes while providing accurate results. It was critically important to preserve at least what was. Therefore, this riskless improvement approach was handy for supply chain companies.

Easier optimization processes

A digital twin is like a drag-and-drop interface when you have dozens of scenarios and can try them. So, the technology allowed businesses to optimize routes, change conditions and make the entire system more efficient, just starting with digital twins. Quick response to any issues helped companies to save a competitive advantage even in the most challenging times.

Predictive analytics

Last but not least. Each digital twin input can be used to create an efficient data model and get accurate predictive analytics illustrating the possible behavior of everything from vehicle to weather. Predictive analytics allows businesses to prevent downtimes, make hardware repairs timely, react to any arising problems immediately and prevent them even before they occur. Consequently, it affects costs, helping companies to reduce them and get more revenue from the supply chain.

Summary

Digital twin only gains momentum since this cutting-edge technology opens even more business and tech opportunities for supply chain businesses. Meanwhile, here everything starts with robust software creation. If you’re looking for a way to run your digital twin with a proven app and ensure centralized management of the entire system – contact the IDAP team. Let’s create a highly performant base for your digital twin shoulder-to-shoulder.